How to Automate Building Design: A Case Study

Earlier work carried out within a tier-one property and construction company focused on exploring how to automate complex building design processes. The industry insights shared here are drawn from that experience, and they continue to shape how Exelsiv approaches AEC automation in design.

Read Part 2: How to Automate Building Design: Product-Informed Digitization

Read Part 3: How to Automate Building Design: Adapting to Local Codes

The Problem

Designing a building is an exercise in managing complexity. Every beam, panel, and connector has its own geometry, strength, and tolerance limits. Each project also has to meet different compliance codes across regions. Traditionally, designers juggle all these factors manually, often repeating the same checks, redrawing the same details, and testing options by hand.

This makes it difficult to:

Enhance productivity by cutting out repetitive processes.

Increase design certainty and reduce rework.

Rapidly optioneer different solutions to find the best fit.

This project explored how the industry could move beyond traditional BIM into true design automation. But this in turn raised the following questions: how can a process that, in some cases, still relies on pen and paper be systemised in a way that can be coded? How can design itself be engineered so that rules, boundaries, and workflows can be digitised, automated, and scaled?

In other words: how do we codify the work of a structural engineer?

The Approach

The solution began with breaking the design process of an engineer down into its systems, rules, and boundaries.

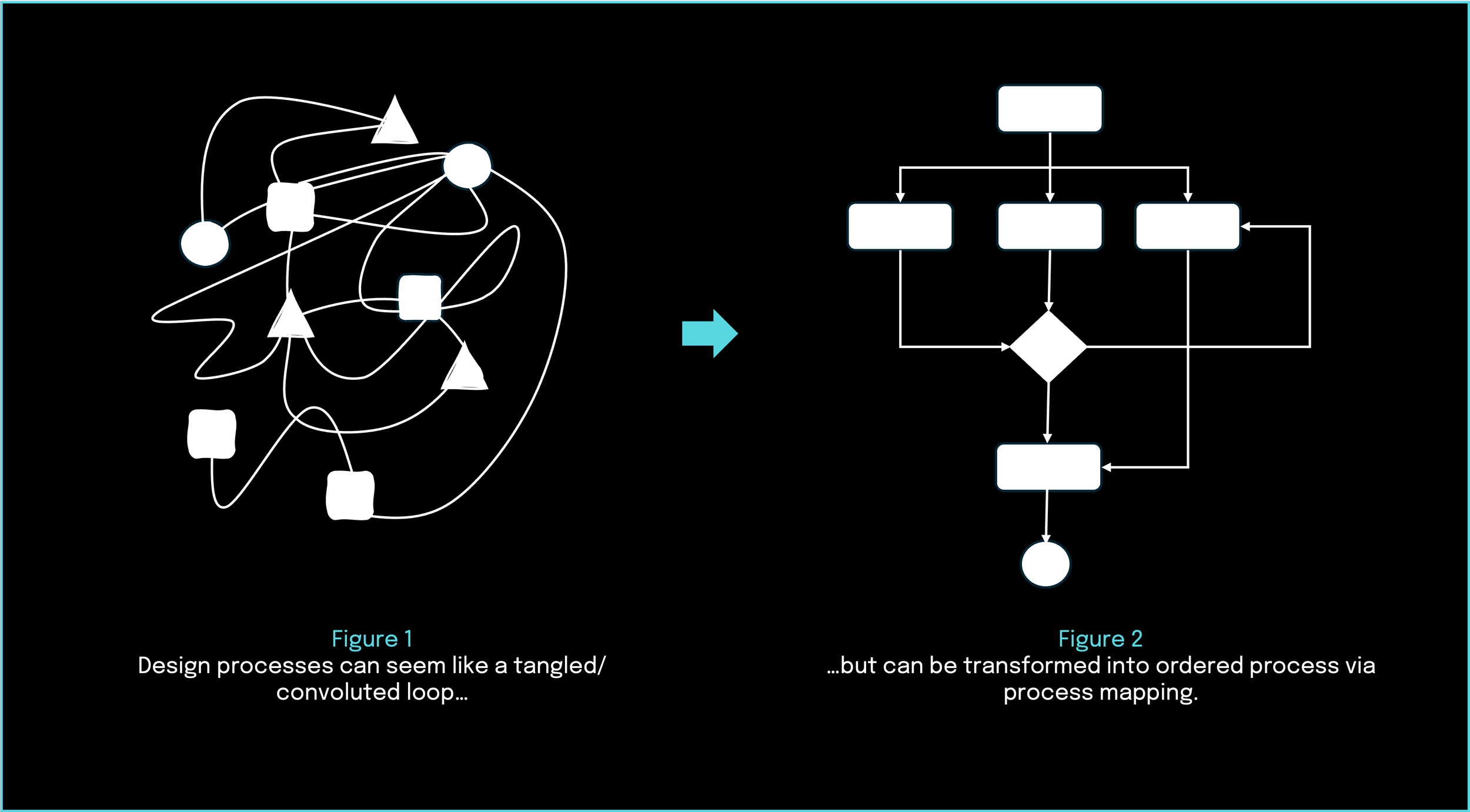

At first glance, engineering work can look like everything happens all at once: iterating, testing, and adjusting in a constant cycle. But when examined closely, the work can be mapped into a structured process. This means:

Identifying key steps and decision points.

Marking coordination points with other disciplines, such as architecture and building services.

Highlighting where redesign is likely to be triggered.

Take, for example, the general process of sizing a structural beam:

The engineer defines the initial geometry and loading conditions.

Coordination with services reveals that ductwork must pass through the same zone.

The design is adjusted, perhaps by increasing beam depth or shifting its location.

That change triggers a knock-on effect in the architectural layout, requiring further coordination.

Once confirmed, the beam selection can be locked in and represented digitally.

What initially appears to be a tangled, reactive loop (see Figure 1) can, through process mapping, be transformed into an ordered and transparent workflow (Figure 2). This shift creates the foundation for automation, because rules and dependencies can only be coded once they are made explicit. This kind of structured thinking reflects the importance of systems thinking in construction.

Beyond BIM

It’s important to be clear: this is not Building Information Modelling (BIM). BIM is a way of representing and coordinating design information. What we’re talking about here is different — codifying engineering rules and boundaries so that decisions can be automated, adapted, and scaled. In other words, moving from information management to true design automation.

The next step was to establish parametric boundaries. Instead of hard-coding rules, design limits such as span, depth, or connection geometry were defined as adjustable parameters. This allowed designs to flex with different suppliers, products, or materials rather than locking the system to a single option.

Equally important was capturing rules in a structured way, so they were clear, consistent, and traceable across disciplines. With this approach, architectural, structural, and services all worked from the same playbook, ensuring alignment and reducing costly mismatches.

Of course, none of this has any value unless it connects to real-world project constraints, like regional building codes, compliance requirements, and the properties of actual products. That integration will be the focus of future case studies.

The Human is Still Present

This automation process did not eliminate the role of the engineer. It instead redefined it. This approach was designed to handle the repetitive, low-value and boring design tasks, while human judgment remained essential for trade-offs, creative solutions, and navigating the unexpected. In fact, codifying these rules freed the engineers to spend more time on higher-value, strategic problem-solving. This balance between automation and expertise was what made the approach both scalable and sustainable.

The Outcome

This approach turned design from a manual, repetitive process into a system that was faster, more reliable, and easier to scale.

Productivity → repetitive checks and redraws were reduced, freeing engineers to focus on higher-value tasks.

Design certainty → with rules and dependencies codified, there was less rework and fewer coordination errors.

Optioneering at speed → different design options could be tested quickly against real-world constraints, helping teams make better decisions sooner.

So what?

The messy, pen-and-paper loops of traditional design were replaced by a transparent, automated workflow. This solved the immediate problems of wasted effort, uncertainty, and miscoordination — while also creating a repeatable foundation for scaling digital design across multiple projects and geographies.

Exelsiv Insight

The lessons from this work continue to inform how Exelsiv helps organisations today. We apply the same principles: mapping processes, codifying rules, embedding compliance, and tying design back to the real world in order to modernise how projects are delivered.

The result is the same ambition: greater certainty, smarter systems, and more productive ways of building.

And this shift is only just beginning. As the industry grapples with labour shortages, housing pressures, and the demand for faster, more efficient delivery, we will see more design automation adopted at scale. Far from replacing engineers, it amplifies their expertise and enables better, faster, and smarter outcomes.

If your organisation is exploring how to make design automation part of its future, Exelsiv can help chart the path forward. Get in touch with us today.